15 Common Tech Pack Mistakes & How to Fix Them

This help to avoid Production Nightmare

Fewer back-and-forth emails

Clear specs → quick approvals

Tolerances & tests reduce QC issues

Fabric & Materials Errors

1. Vague Descriptions

Factories can’t guess. Ambiguity leads to incorrect materials and colors.

Don’t: “Blue cotton fabric”

Do: “100% Cotton Jersey, 180 GSM, Pantone 19-4052 TCX”

2. Skipping BOM Details

Missing trims/threads/labels halts production while the factory waits.

Don’t: Leave trims unspecified

Do: List all: YKK zipper, Gutermann thread, care label…

3. Ignoring Feasibility

Specifying techniques not available locally causes delays & costs.

Don’t: Demand a stitch the machines can’t do

Do: Confirm capabilities with factory upfront

Measurement & Fit Errors

4. Incomplete Measurement Specs

Missing POMs means the factory guesses the fit.

Don’t: Provide only chest & length

Do: Include sleeve, waist, hip, rise, inseam…

5. Missing Tolerances

Without ±, QC becomes subjective and disputes rise.

Don’t: Waist: 80cm

Do: Waist: 80cm (Tolerance: ±1cm)

6. Inconsistent Data

If size chart says 50cm but diagram says 52cm → chaos.

Don’t: Let pages contradict

Do: Cross-check all numbers

Design & Artwork Errors

7. No Clear Visuals

Text-only is misread. Pictures + callouts remove ambiguity.

Don’t: “Add pleats to the front.”

Do: Sketch + labelled diagram of knife pleats.

8. Unclear Artwork Placement

“Place logo on chest” is vague—spec exact position & method.

Don’t: “Small logo on sleeve.”

Do: 5 cm logo, 10 cm down from shoulder seam, embroidery.

Process Errors

9. No Version Control

Old files get used if versions aren’t crystal clear.

Don’t: TechPack_Final.pdf

Do: Style123_v2.1_2025-10-03.pdf

10. No Testing Requirements

If you don’t ask for tests, you won’t get them.

Don’t: Assume “standard tests”.

Do: List AATCC/ISO tests (e.g., AATCC 135).

11. Assuming the Factory Knows

Never leave decisions open—spec every detail.

Don’t: “Use standard stitching.”

Do: “Single-needle lockstitch, 12 SPI.”

Compliance & Finishing Errors

12. Language Ambiguity

Terms may not translate—use diagrams for clarity.

Don’t: “Godet insert” (text only)

Do: Labelled diagram of godet placement.

13. Over-complicated Layout

Cluttered packs are slow to read & easy to misread.

Don’t: Cram everything on one page

Do: Use clear sections: BOM, POM, Construction, Grading…

14. Care Label Errors

Wrong content/symbols → legal risk & damage.

Don’t: Guess wash symbols

Do: Verify all destination-market requirements.

15. No Packaging Instructions

Folding/bagging/boxing affect arrival condition.

Don’t: “Pack and ship.”

Do: Specify fold, polybag, carton size, units/box.

Ask an Expert

Describe your problem and get factory-ready guidance.

✨ Professional Advice

Related Posts

Vietnam: A Textile-to-Garment Giant 28 Nov 2025

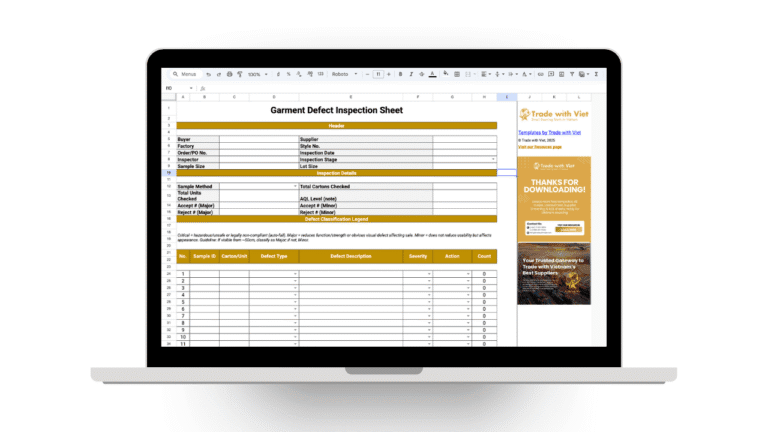

Vietnam: A Textile-to-Garment Giant 28 Nov 2025 Garment Defect Inspection Sheet Template 10 Oct 2025

Garment Defect Inspection Sheet Template 10 Oct 2025 Behind the Seams: A Practical Guide… 09 Oct 2025

Behind the Seams: A Practical Guide… 09 Oct 2025