The Inspector's Field Guide

A practical infographic for understanding Acceptable Quality Limit (AQL) standards in apparel manufacturing.

What is AQL? It’s Risk Management.

You can’t check 15,000 shirts one by one. AQL uses statistical sampling to judge the whole lot from a small, random sample — balancing quality control with reality on the factory floor.

Critical Defects

0%

Hazardous/unsafe. One is enough to fail the entire lot.

Major Defects

2.5%

Likely customer return. Affects appearance or use.

Minor Defects

4.0%

Small imperfections customers rarely notice.

The 6-Step AQL Inspection Flow

From a huge lot to an “Accept/Reject” decision — fast and defensible.

Gather Info

Get Code Letter

Find Sample Size

Inspect Sample

Classify Defects

Make the Call

A Practical Example: 15,000 Polo Shirts

See the sample size & the pass/fail thresholds at a glance.

From Lot to Sample

Lot size 15,000; Inspection Level II → inspect only a fraction.

Accept vs. Reject Thresholds

For a sample of 315 units, the difference between pass and fail can be a single defect.

On The Floor: Defect Classification

Align your team on definitions to keep calls consistent.

⚠️ Critical

- Broken needle in garment

- Sharp objects in packaging

- Incorrect flammability labels

- Evidence of mold or infestation

❌ Major

- Large, noticeable stain or hole

- Open seam or broken stitches

- Non-functioning zipper/button

- Measurement out of tolerance

- Significant color mismatch

- Missing brand or care label

➖ Minor

- A few untrimmed threads

- Small, inconspicuous spot

- Slight seam puckering

- Single skipped stitch

✨ AI Inspector’s Toolkit

Enter Inspection Data

Generated Report Summary

Select Common Defects

Suggested Actions

Related Posts

Vietnam: A Textile-to-Garment Giant 28 Nov 2025

Vietnam: A Textile-to-Garment Giant 28 Nov 2025 15 Common Tech Pack Mistakes &… 22 Oct 2025

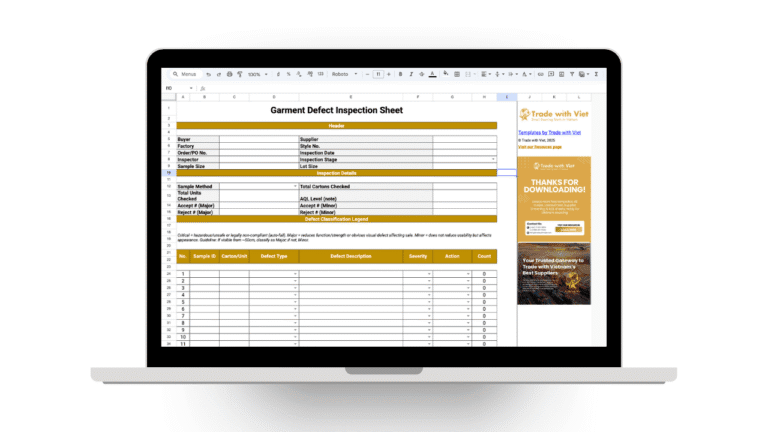

15 Common Tech Pack Mistakes &… 22 Oct 2025 Garment Defect Inspection Sheet Template 10 Oct 2025

Garment Defect Inspection Sheet Template 10 Oct 2025